Table of Contents

Understanding Manufacturing ERP Specialization

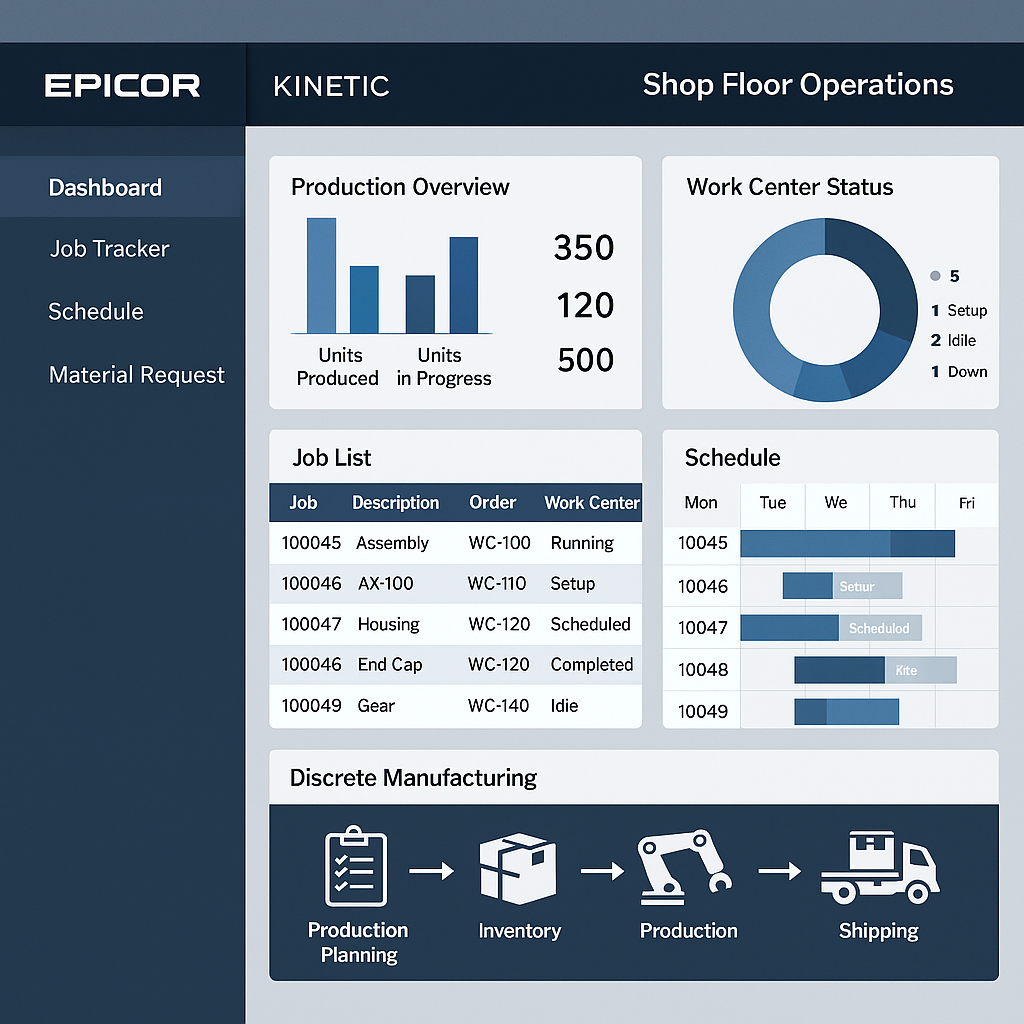

In the world of Enterprise Resource Planning (ERP), there’s a constant tension between general-purpose platforms and industry-specific solutions. While broad platforms offer flexibility, they often require extensive customization to meet the unique demands of a sector like manufacturing. This is where systems like Epicor Kinetic have carved out a significant niche. Instead of being an all-purpose business tool, it’s engineered to be the central nervous system for the modern factory.

My analysis of enterprise systems, distilled from observing countless deployments, indicates that manufacturing ERPs live or die by their ability to connect the shop floor to the top floor. It’s not enough to manage financials; the system must understand the language of work orders, bills of materials (BOMs), and machine availability. Epicor’s strength has traditionally been in this deep, vertical integration for discrete manufacturers (companies that build distinct items like machinery, electronics, or automotive parts). This specialized focus allows it to address the granular complexities of production that a generalist ERP might overlook or handle less efficiently.

What Makes a Manufacturing ERP Different?

Core Manufacturing ERP Differentiators

So, what sets a system like Epicor Kinetic apart from a more financially-oriented ERP? The difference is in the core data model and the workflows it supports. It’s not just about adding a manufacturing module; it’s about having manufacturing principles embedded at its very foundation.

- Deep Production Management: It’s built around core manufacturing concepts like job costing, material requirements planning (MRP), and advanced planning and scheduling (APS). The system is designed to calculate the true cost of a manufactured good by tracking labor, materials, and overhead with granular detail. This level of precision is crucial for accurate profitability analysis and competitive pricing.

- Integrated MES Capabilities: Modern versions increasingly embed Manufacturing Execution System (MES) functionality. This means the ERP isn’t just sending orders down to the floor; it’s receiving real-time data back from machines and workers. This data flow allows for immediate visibility into production progress, quality control issues, and operational efficiency (OEE). Such integration helps identify bottlenecks quickly and enables proactive adjustments to production schedules.

- Supply Chain Synchronization: A manufacturing ERP must also tightly integrate with supply chain processes. Epicor Kinetic helps manage supplier relationships, procurement, and inventory, ensuring that raw materials are available when needed and finished goods are shipped efficiently. This holistic view is essential for minimizing disruptions and optimizing lead times.

This is a fundamentally different approach than that taken by many ERPs, which might treat manufacturing as just another module. For Epicor, it’s the entire reason for being. This focus is similar to what we see in other specialized systems, like the asset-intensive focus of IFS Cloud, proving that deep vertical knowledge remains a powerful competitive advantage.

The Cloud Evolution with Kinetic

Embracing Cloud-Native Architecture with Kinetic

The “Kinetic” branding represents Epicor’s significant push toward a modern, cloud-native architecture. This isn’t just about moving servers to the cloud; it’s about redesigning the user experience and embracing a more composable, browser-based interface. This transition is crucial for several reasons. It lowers the barrier to entry for mid-market manufacturers who can’t afford a massive on-premise IT footprint. It also simplifies access for a mobile workforce, allowing a plant manager to check production status from a tablet, not just a desktop in a back office. Furthermore, cloud deployment often means faster updates, enhanced security, and greater scalability, which are all critical for dynamic manufacturing environments.

Positioning Against Market Competition

Longitudinal data from the ERP market shows that this cloud adoption is critical for legacy players to stay relevant against born-in-the-cloud competitors. While large-scale systems like Microsoft Dynamics 365 F&O serve the upper market, Epicor Kinetic is positioned as a powerful, purpose-built solution for the complexities of mid-market manufacturing. It demonstrates that for certain industries, a specialized tool will almost always outperform a generalist one, especially when that tool is designed from the ground up to meet specific operational demands.

I’m interested in hearing other perspectives on vertical-specific ERP. Connect with me on my LinkedIn profile to share your insights.